Prefab steel buildings have earned a spot as a top choice for many property owners because of their quick assembly and durability. In Canada, where weather conditions can be challenging, these structures make an appealing option. Understanding how to properly install a prefab steel building can save time and minimize future issues. When you get the installation right, you get a structure that not only stands strong against the elements but also benefits from maximum efficiency.

Why are prefab steel buildings so appealing? They offer a straightforward assembly process compared to traditional construction. Imagine piecing together a giant jigsaw puzzle where each part is crafted to fit perfectly. This approach means reduced construction time and fewer complications. Embracing these structures requires some upfront preparation, but the benefits make it all worthwhile.

Preparing the Site

Before jumping into installation, the first and most important step is preparing the site. Unlike a regular backyard project, setting the stage for a steel building requires attention to detail. Think about it like planting a tree: the healthier the soil, the stronger the tree will grow. Similarly, a well-prepared site ensures your building has a solid foundation.

Here’s what you should consider when preparing the site:

1. Obtaining Permits: Check with local authorities to find out what permits or approvals you need before starting construction. Rules can vary, and skipping this step can lead to trouble down the road.

2. Ensuring Stable Ground: It’s crucial to have level ground to support the structure. Use equipment to even out any dips or rises and remove any large rocks or debris.

3. Clearing the Area: Remove trees, bushes, or any obstacles from the site. This doesn’t just make room for the building but also ensures nothing obstructs the assembly process.

4. Marking the Boundaries: Define where the building will sit using stakes or spray paint. This step helps visualize the building’s footprint and ensure everything is in the right place.

By following these steps, you create a safe and practical foundation for the assembly process. Each point in the checklist sets the groundwork—not only physically but also mentally—for a smooth installation. As you prepare, know that your efforts will lay the path for a building that serves its purpose reliably for years.

Assembling the Foundation

Once the site is ready, the next step is to focus on the foundation, which acts like a sturdy backbone for your steel building. Different types of foundations offer unique benefits, so selecting what’s best for your project is crucial.

Let’s look at a few popular options:

– Slab Foundation: This is a common choice where concrete is poured directly onto the ground, providing a solid base that supports the entire structure. It’s excellent for areas with stable soil and is often quicker to install.

– Pier Foundation: If you’re dealing with uneven terrain, a pier foundation can be ideal. It involves placing concrete piers deep into the ground, allowing the building to stand above the soil. This method works well in areas prone to moisture accumulation.

– Perimeter Walls: For situations that require additional stability, perimeter walls provide excellent support around the edges, bolstering the overall strength of the building.

Taking the time to understand these options helps in making informed decisions about which foundation best meets the specific needs of your project.

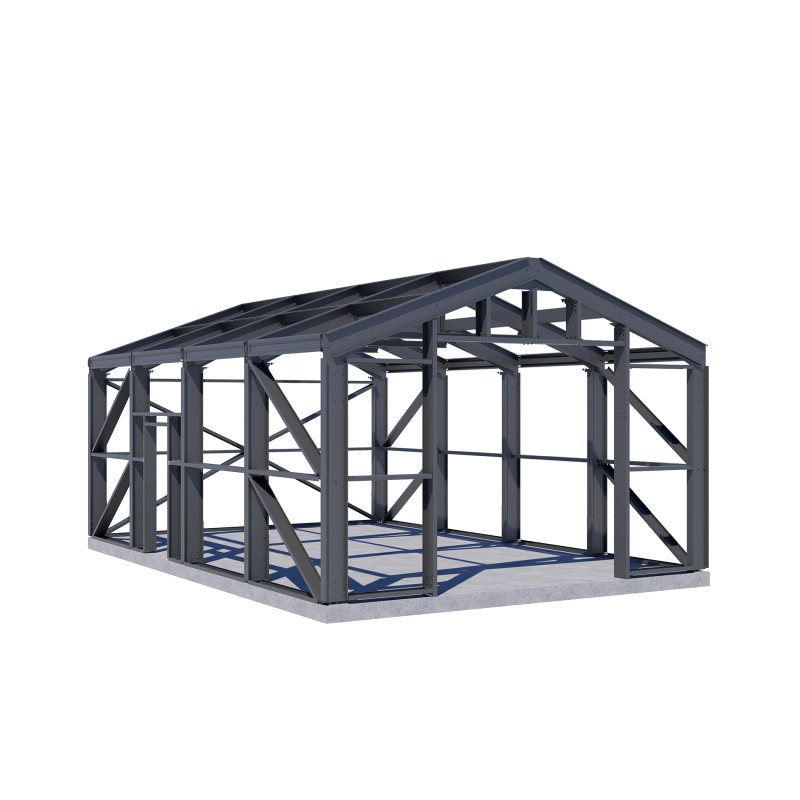

Constructing the Frame

With the foundation laid, building the steel frame is the next hallmark of the installation process. Think of it as putting together the skeleton of the building. Here, precision takes the driver’s seat.

1. Follow the Blueprints: Start by carefully reviewing the blueprints provided. Aligning each piece according to the plan ensures that all parts fit together smoothly.

2. Assemble Sections: Many prefab buildings arrive in easily manageable sections. Begin combining these sections on the ground, checking for any misalignments before lifting them into place.

3. Check for Levelness: Use levels frequently as you secure connections to guarantee everything sits straight and true.

4. Secure the Frame: Once in position, tighten all bolts and fasteners to lock the structure firmly together. Double-check all connections for any signs of looseness.

Attention to these steps not only sets the stage for durability but makes future phases like insulation much easier to tackle.

Insulating and Sealing

Now, think about what’s happening between those steel walls. Insulation acts like a warm coat in winter and a cooling shade in summer, making the building comfortable year-round. Choose insulation that suits your local climate; options include fiberglass, spray foam, or rigid boards.

– Install Insulation: Place insulation panels between steel studs. Ensure complete coverage to maximize efficacy.

– Seal the Joints: Seal all seams and joints with weatherproof caulking or tape to prevent drafts and moisture penetration. This step also contributes to energy savings by reducing heating and cooling requirements.

Getting the insulation and sealing right is key to creating a building that’s not just energy-efficient but also cozy and dry in all seasons.

Adding Finishing Touches

With the structure up and insulated, add the finishing touches. This wraps up the construction and gives the building its functional edges.

– Doors and Windows: Install doors and windows, checking for smooth operation and tight seals. Properly fitted openings help maintain comfort inside the building.

– Final Fixtures: Apply any trim or final fixtures to enhance both appearance and utility.

– Safety Checks: Go over the entire structure and conduct safety inspections on all bolts, fasteners, and connections. Ensuring everything is secure protects the integrity of the building.

When the finishing touches come together, the steel building becomes a cohesive, robust space ready for use.

Your Future-Ready Building

By following these steps, you’re not just constructing a mere shelter, but cultivating an enduring asset. Prefab steel buildings bring flexibility and resilience, skillfully blending practical needs with robust performance. As you enjoy the fruits of careful preparation and construction, you know the building stands ready to serve, day in and day out.

Harnessing the capabilities of prefab steel buildings aligns with both present realities and future aspirations. Whether you’re housing equipment, setting up a workshop, or creating extra space, these buildings offer a tangible path to achieve your goals, meeting both immediate needs and long-term visions.

For those ready to take the next step in creating a durable and efficient structure, Dutech Structures offers an array of options suited to your needs. Discover more about prefab steel buildings and how they can transform your space into a reliable asset, withstand Canadian weather conditions, and offer a fast and affordable solution.