February tends to be one of the busiest months for building in cold regions like Canada, especially when projects need to stay on schedule despite the weather. One material we reach for this time of year is insulated wall panels. These panels are built with both warmth and strength in mind, which makes them a dependable part of any winter construction plan. Knowing what they’re made of and how they work can help your planning stay on track, even when the temperature drops below freezing.

Choosing the right materials during the colder months can reduce delays, save energy, and protect the structure while other parts of the job move slowly. When we work with insulated wall panels, we make sure every step benefits from both speed and durability. Let’s look at how they’re built, why February is a smart time to use them, and how to get the most from them throughout the season.

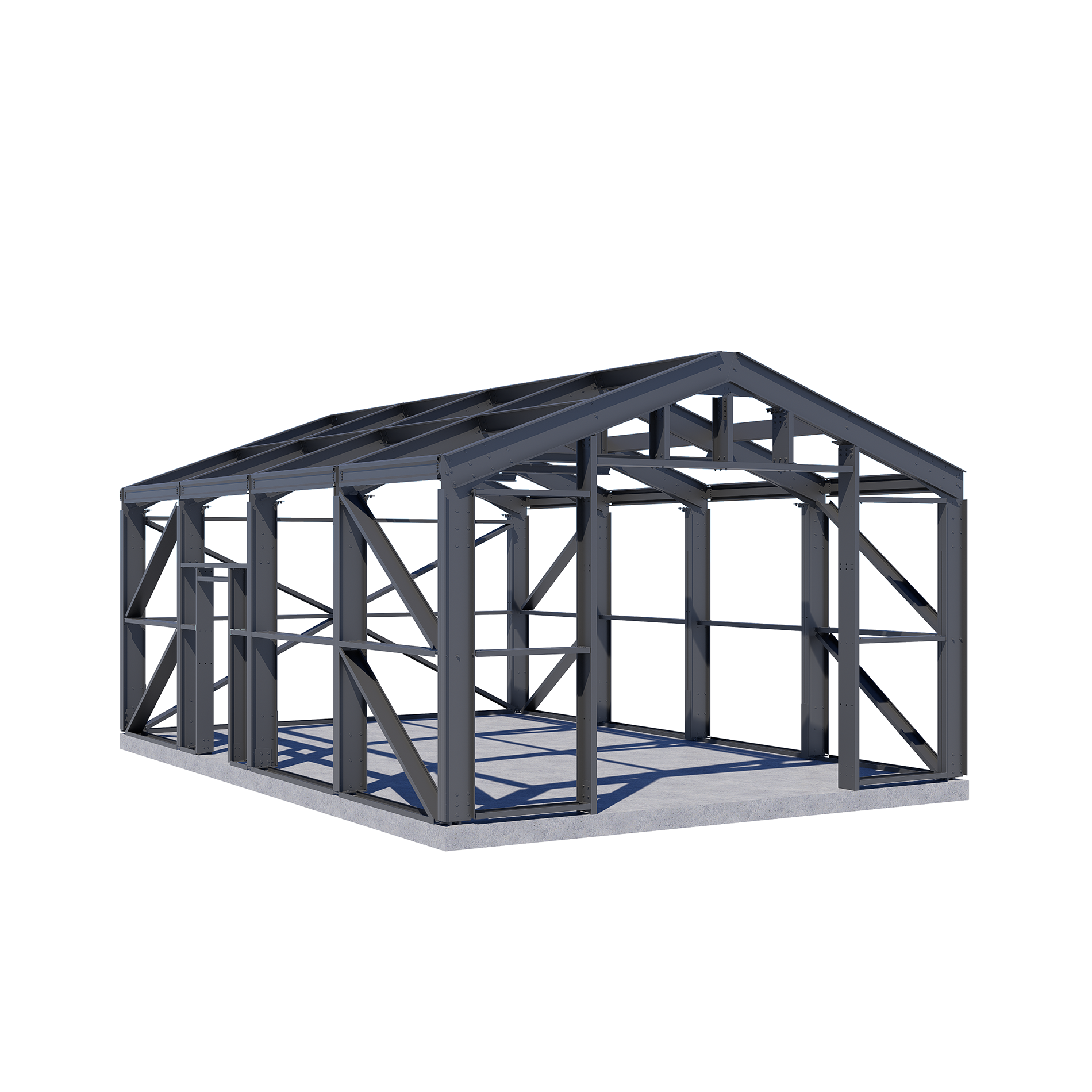

What Insulated Wall Panels Are Made Of

Insulated wall panels may look simple at first, but each panel is made of several tightly connected layers, each with a specific job. At the core is a rigid insulation layer, commonly made from materials like expanded polystyrene (EPS), polyurethane, or polyisocyanurate. That layer is sandwiched between two outer panels, often steel or aluminum, which give the panels their structure and protect them from damage.

Each part plays a role in helping the panel do what it’s supposed to:

• The insulation core traps heat inside and blocks cold air from getting in

• The outer metal skins keep the panel strong and hold up against wind, snow, and moisture

• Together, the layers create a barrier that keeps the building warmer without needing as much heating

When used during a winter build, those panels mean fewer gaps where cold air can get in. They also make it easier to build with confidence, knowing that the wall will perform as expected once the heating system kicks in.

The different types of insulation used in these panels let us pick the right fit for the project. Expanded polystyrene is commonly chosen for its lightweight quality and solid insulation, while polyurethane and polyisocyanurate are well-known for stopping heat loss and working great in colder climates like Canada. The outer metal skins, whether steel or aluminum, are tough enough to handle heavy winter winds, blowing snow, or anything else the season throws at them. When these layers are pressed tightly together, they not only add strength but also make the panels work as a solid shield against moisture and the cold.

Beyond structure and insulation, how these layers fit together during manufacturing is part of what makes insulated wall panels so useful for winter work. The seams between the panels are designed to lock out drafts, so even after a quick install, the building isn’t left with weak points where the air could sneak in.

Why February Is a Good Time to Use Them

One of the biggest hurdles for February construction is dealing with freezing temperatures. That’s where insulated wall panels start to shine. They help guard against heat loss the moment they go up, which helps crews keep indoor temperatures higher once the structure is enclosed.

Cold weather is also a time when we need to keep the job moving. Since these panels arrive pre-measured and pre-assembled, they go up quickly and don’t need as much adjusting on site. That means fewer hours outside in below-zero weather trying to get standard walls sealed tight.

There’s another added benefit this time of year. Getting wall panels up without delay cuts down on the time that other parts of the interior are exposed to cold air and snow. A fast wall system protects wiring, insulation, and even drywall from those outdoor conditions while the rest of the build continues.

The winds and snow of February can slow down normal construction methods, but insulated wall panels change that. These panels are engineered so that once they’re on site, their fit and finish mean our crews can work faster, snap panels into place efficiently, and move from one section of the building to the next with little down time. Less handling and fewer steps mean less chance for cold and snow to cause setbacks. Even if weather changes quickly, a crew using insulated panels can make steady progress and keep the build moving ahead.

Where These Panels Help Most

Not every wall has the same job, but some areas of a building need more protection than others during winter. That’s where smart placement of insulated wall panels makes a big difference.

• Outer walls face the wind, snow, and big temperature swings, so using panels there helps trap heat and block drafts

• Inside cold storage or spaces that must stay at a steady temperature, these panels do extra work by controlling internal zones

• When adding onto an existing building in winter, panels make it easier to match quality insulation with less mess and faster setup

Their flexibility means we can use these panels in places that need both strength and comfort. And during February, having fewer materials to work with makes setup smoother and more predictable, even when the forecast changes fast.

Garages and shops that see lots of door openings during the winter can quickly lose heat. By placing insulated wall panels on exposed sides, we stop the worst drafts and make sure the temperature inside doesn’t drop every time the door rolls open. In barns or sheds where animals, machinery, or supplies need to stay warm, insulated panel walls help hold the line against overnight chills. Warehouses or workshops that rely on steady heating keep costs in check by not letting all that warm air slip outside through the walls. Some of our customers use panels for storage areas where moisture could be a big problem. With insulated panels, the buildup of condensation on walls is much less likely, and supplies stay dry and better protected.

Tips for Making the Most of Panel Installation

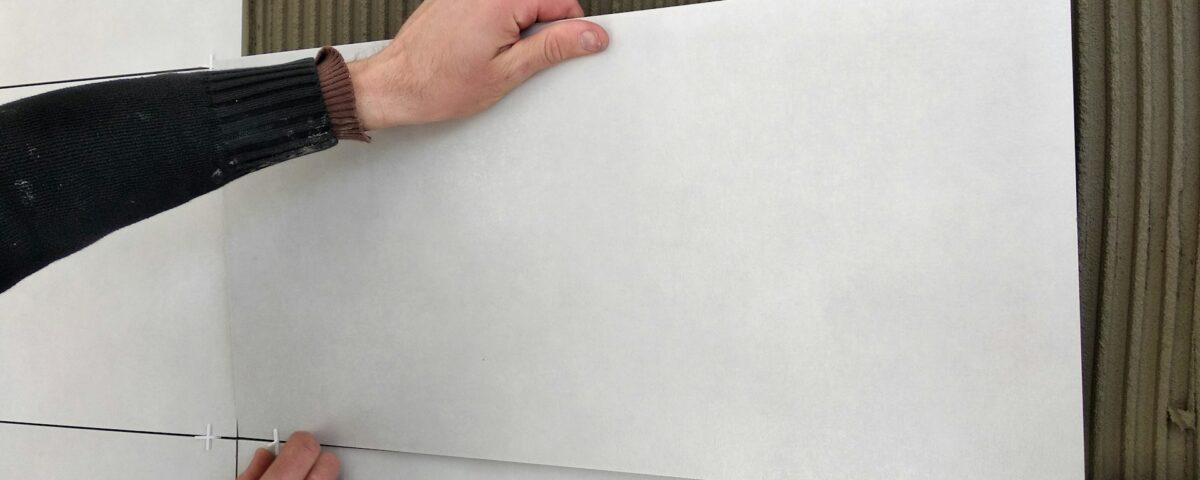

Using the right material is only the first step. How we handle and install panels matters just as much when the weather is cold and wet. A few simple habits can go a long way in keeping the job on track and the final result solid.

• Partner with people who know how to handle panels in cold weather. Not all materials respond the same when frozen, so having the right crew helps avoid damage.

• Keep panels covered and dry before installation. Snow, slush, or ice can lead to problems if they get caught between layers before sealing.

• Once the panels are in place, we double-check seals around windows, doors, and corners to prevent heat loss later on.

A little care up front avoids headaches down the road and helps your panels perform better once everything is buttoned up and in place.

On very cold mornings, make sure to schedule extra breaks so workers can handle the panels without rushing. Before moving insulated panels into place, sweep off any ice or snow to get a tight fit and stop moisture from being trapped inside. When building where temperatures swing up and down fast, keep the panels in a covered spot until just before they go into the wall. This helps reduce warping and damage and lets the panels slot into place exactly as they’re meant to. After installation, check for any spots that might have gaps. It’s easier to fix those right away before the cold has a chance to find its way in.

Staying Warm and Building Smart

February comes with its share of challenges, but it doesn’t have to slow things down. When we use insulated wall panels wisely, we can move forward with less worry about heat loss, moisture, or timing setbacks. These panels are built to work in the cold, and with the right prep, they do their job well from the moment they’re installed.

Planning for materials that work with the season instead of against it gives us more control over the outcome. Even when other parts of a winter project might move slower, our walls don’t have to. The goal is a warmer, tighter, more efficient space that stands up to the season and gets us one step closer to finishing strong.

Planning cold-weather construction in Canada can be challenging, but over the years, we’ve relied on our insulated wall panels to keep projects running on schedule without compromising quality. Their built-in strength and thermal efficiency help prevent winter delays and boost your project’s efficiency right from the start. Reach out to Dutech Structures today to discover how we can help support your next build.